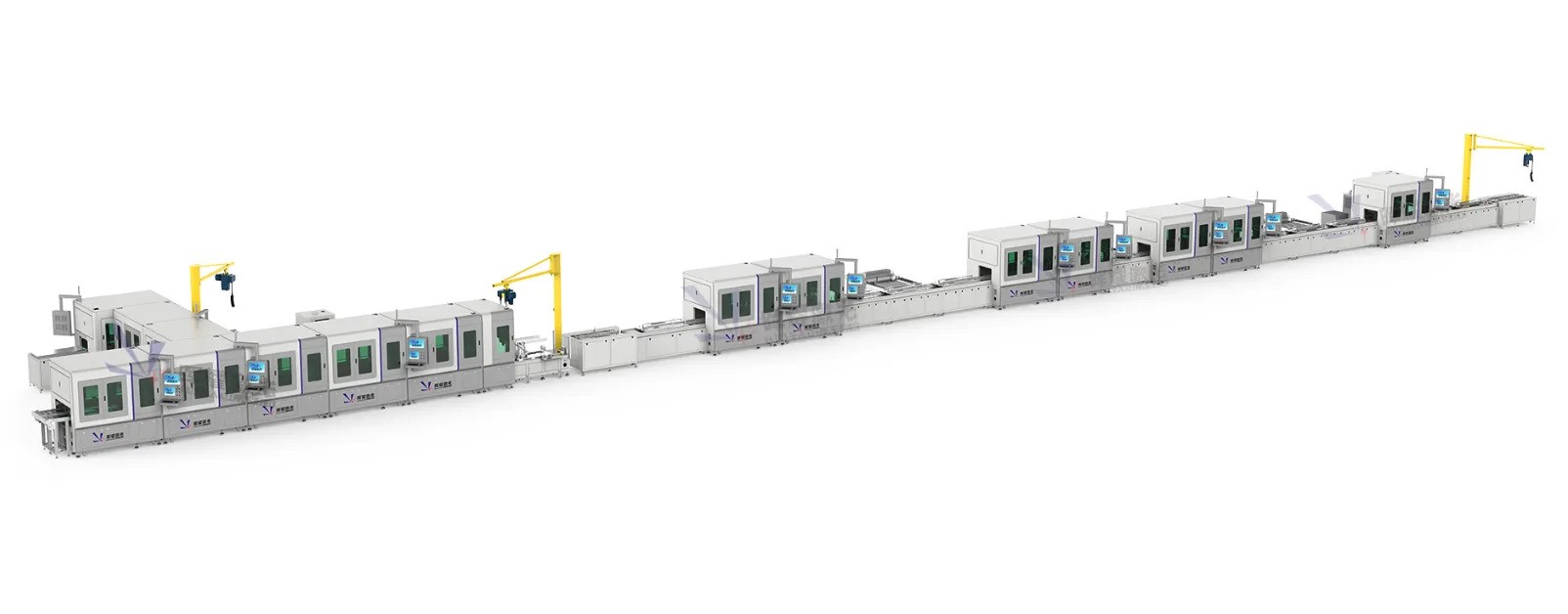

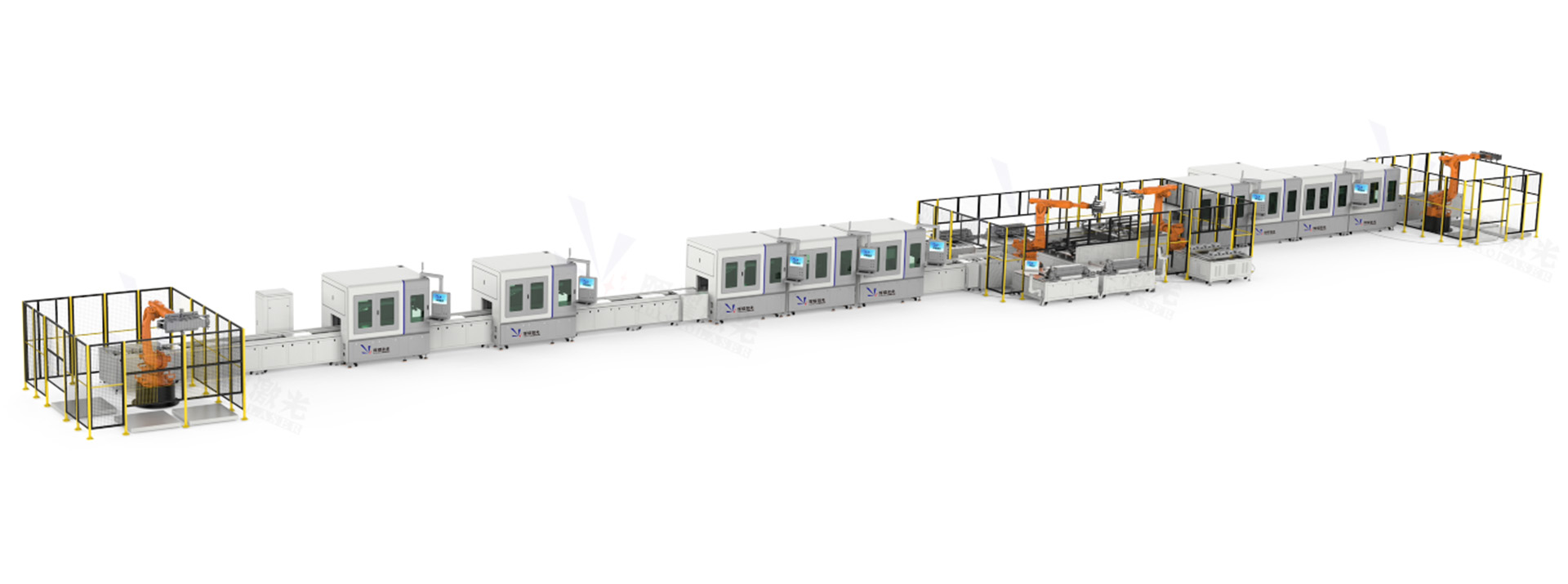

Prismatic Battery Module Assembly Line

Introduction

Welcome to the cutting-edge realm of battery module manufacturing, powered by HuiYao Laser's revolutionary Prismatic Battery Module Assembly Line. As a leading innovator in laser technology, HuiYao Laser is proud to introduce a state-of-the-art solution that redefines the standards of efficiency, precision, and scalability in the battery industry.

In a world where energy storage solutions are paramount to sustainable development, battery modules play a vital role in powering electric vehicles, renewable energy systems, and various other applications. At Yao Laser, we understand the critical importance of delivering high-performance battery modules that meet the demands of a fast-paced and environmentally conscious world.

Our battery module automation production line stands at the forefront of advanced manufacturing technology, designed to streamline and elevate the production of battery modules like never before. From concept to execution, every aspect of this automated production line has been meticulously crafted to revolutionize battery manufacturing and empower businesses to thrive in a competitive landscape.

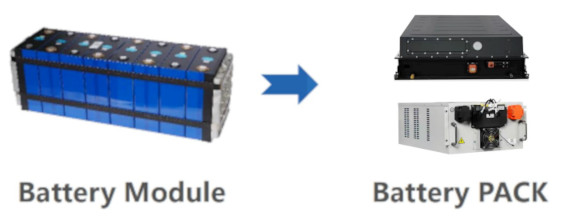

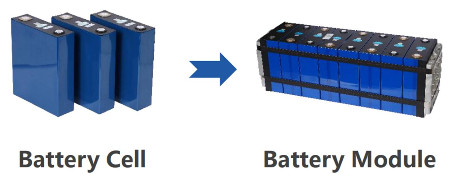

Output

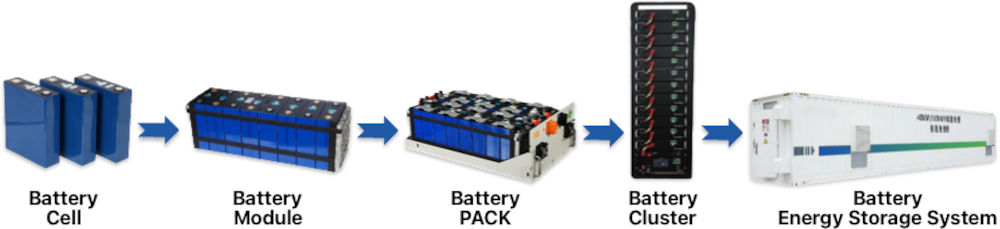

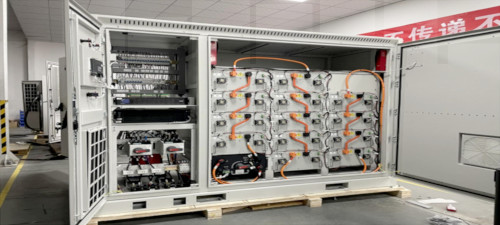

Prismatic Battery Module

Product Applications

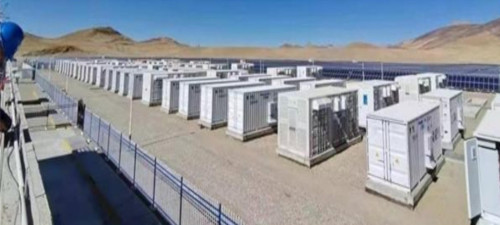

- Energie Storage Battery Packs.

- Industrial and Commercial Energy Storage.

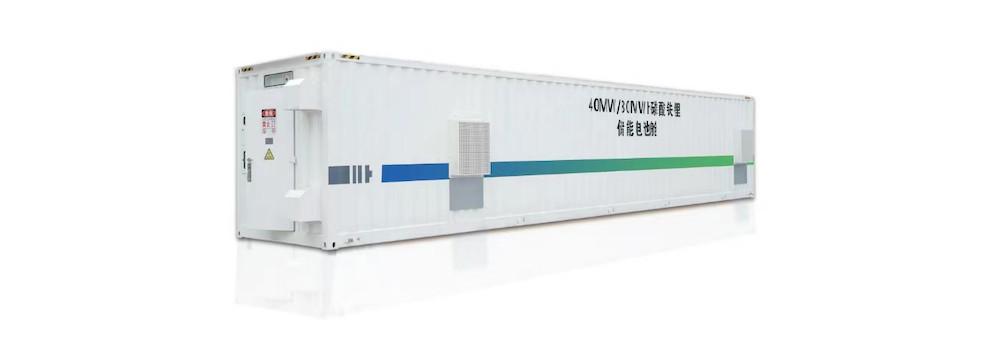

- Energy Storage Container.

- Residential Energy Storage.

- Electric Vehicles.

- Power battery.

Technical Highlight

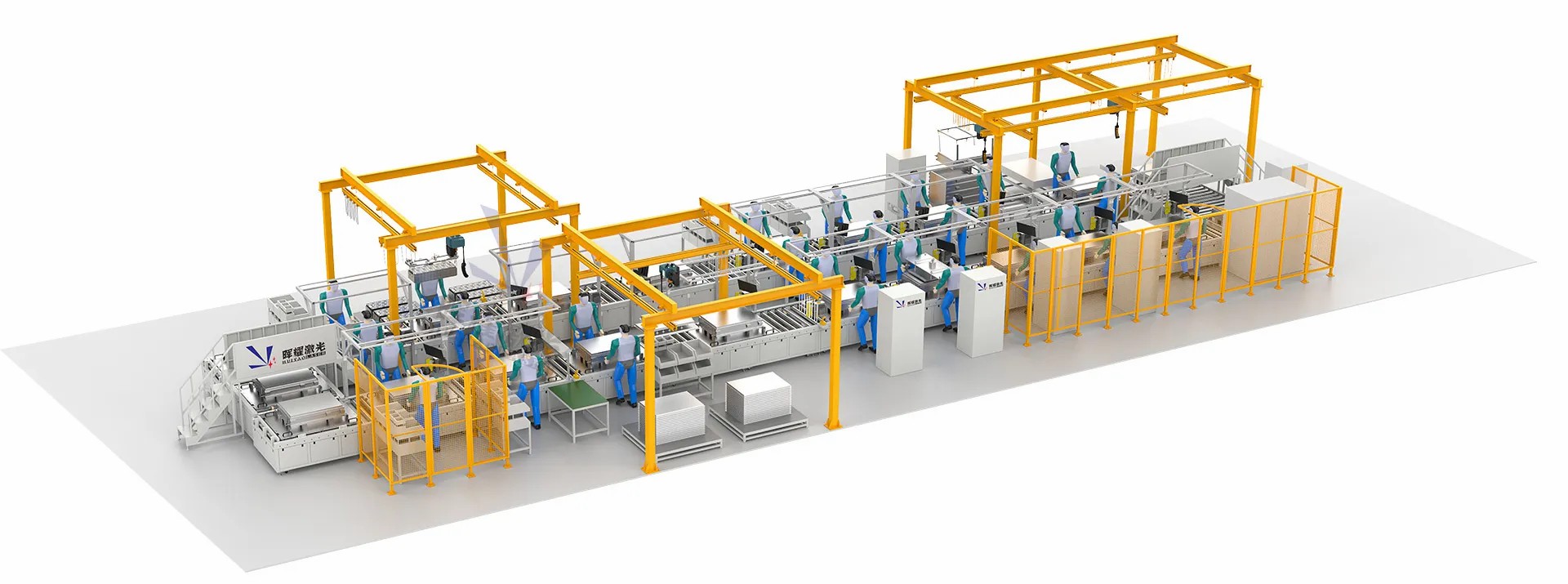

- Industry-Leading Efficiency: Time is of the essence in battery module production. Yao Laser's automation production line is engineered for maximum efficiency, minimizing cycle times and optimizing throughput. Automated processes, synchronized workflow, and real-time data integration enable unparalleled productivity.

- Unrivaled Precision and Quality: Precision is the cornerstone of excellence in battery module manufacturing. Our production line leverages cutting-edge laser technology and advanced robotics to ensure precise assembly, positioning, and welding of battery components. The result is battery modules of uncompromising quality and performance.

- Flexibility and Adaptability: The diverse landscape of battery applications demands versatility. Yao Laser's automation production line offers flexibility to accommodate various battery module designs, sizes, and specifications. Whether for electric vehicles, energy storage, or aerospace applications, our production line caters to your unique requirements.

- Seamless Integration and Smart Automation: Seamless integration of machinery and automation systems ensures a cohesive and intelligent production line. Our smart automation solutions enhance process control, reduce downtime, and optimize resource utilization, all while requiring minimal human intervention.

- Safety and Sustainability: We prioritize the safety of operators and the environment. The production line is equipped with advanced safety features, adhering to international safety standards. Furthermore, our commitment to sustainability is reflected in the production line's energy-efficient design and eco-friendly practices.

- Avec un héritage d'innovation et une quête incessante de l'excellence, la ligne de production automatisée de modules de batterie de Yao Laser est à l'avant-garde de l'évolution de l'industrie des batteries. Adoptez la puissance de l'automatisation et de la fabrication avancée, et propulsez vos capacités de production de modules de batterie vers de nouveaux sommets.

With a legacy of innovation and a relentless pursuit of excellence, Yao Laser's battery module automation production line is at the vanguard of the battery industry's evolution. Embrace the power of automation and advanced manufacturing, and take your battery module production capabilities to new heights. Join us in shaping a future of sustainable energy solutions, driving progress, and making a positive impact on the world with Yao Laser's battery module automation production line.

Technical Parameters

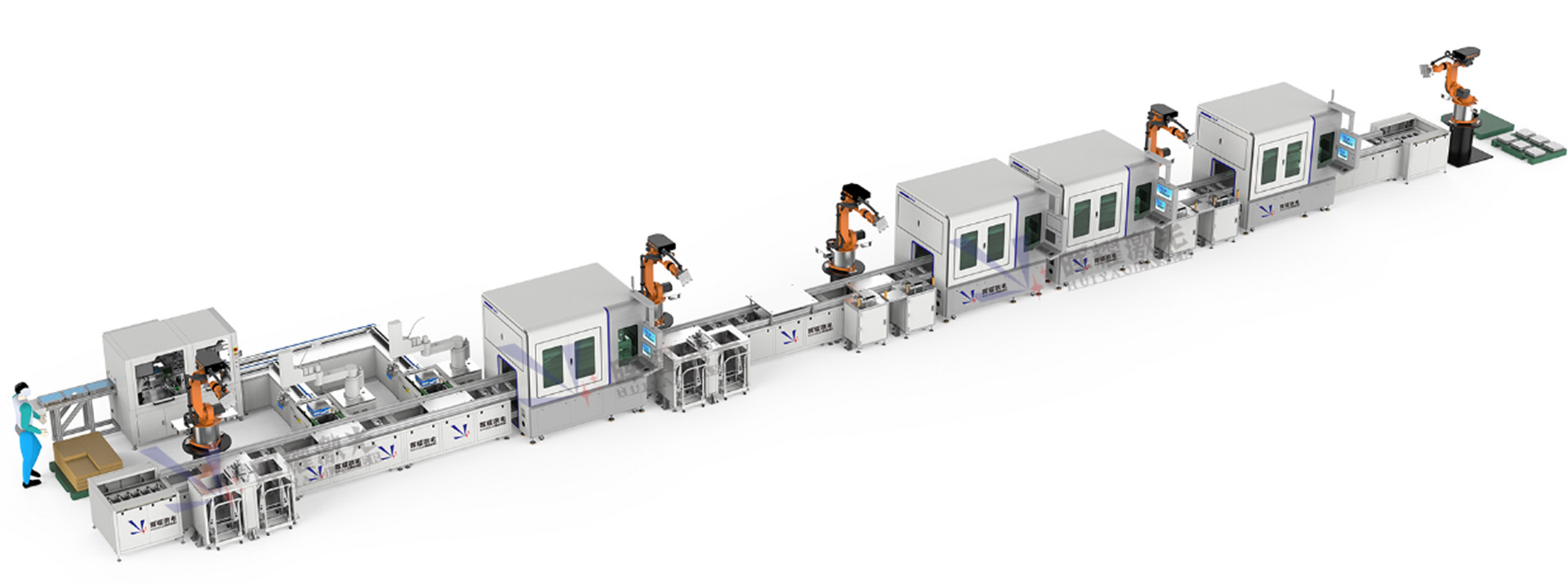

- Equipment production capacity greater than or equal to 10-12PPM .

- Final yield rate greater than or equal to 99.8% (calculated only for defects caused by the equipment).

- Equipment failure rate less than or equal to 2%.

- Compatible with multiple module size specifications, allowing for quick changeovers.

- Laser output power stability (fluctuation) less than or equal to ±1%.

- Digital display and adjustment of mirror focal length, with a range of -5.0 to +5.0mm and an adjustment accuracy of less than or equal to 0.5mm.

- Welding trajectory edited using welding software, with an automated welding process and adjustable parameters. User permissions for operation and modification can be set.